What is shot firing used for in a quarry? Haladjian Minerals Solutions explains you everything!

The question we all ask ourselves: what is shot firing?

During the exploitation of a quarry, the extraction of massive rock is necessary for the production of aggregates. Shot firing allows a section of rock to be knocked down with explosives in order to reduce its size and carry out a first crushing of the rock. It can be done in some quarries up to twice a week to meet material needs.

For residents around the quarry, it is this extraction method that generates the least impact in terms of seismic waves and aerial vibration waves. Shot firing is performed at frequencies to be respected in the month with slots during the day to carry out the extraction of materials.

How does shot firing take place?

Initially, it is carried out at a very specific location in the quarry depending on the mass to be blasted and the rock deposit. According to that, the volume of explosive to use is different. The result of very precise calculations is then given to the miners for the preparation of the explosive.

Here are the steps to shot firing:

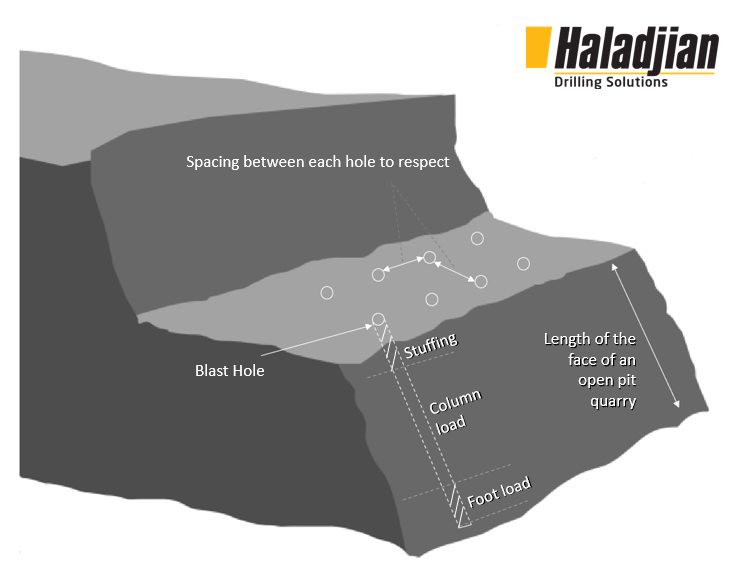

The first step is the hole where the explosive is going to be inserted. A driller uses a drill to make holes in very specific places, with a spacing to be respected between each of them. It is then necessary to proceed to the filling of the holes in explosives. Some holes may be more or less loaded with explosives depending on the hardness of the ground. It is possible that the rock is more friable in certain places, hence the importance of having more or less energy during the extraction of the rock.

An electrical connection is made between each explosive charge, the security of the premises is done as well as the installation of seismographs around the blast hole.

During shot firing, quarries must comply with a prefectural decree with different standards for each of them, depending on their location and the surrounding environment. Some have stricter restrictions than others.

Once all the standards are respected and the site has been secured, the blast can take place.

Here is a drawing of how shot firing is executed:

Once the blast took place, the rocks are extracted using loaders then are loaded and transferred by dumpers to the fixed plant. The blocks of rock are crushed there to obtain aggregates of different sizes. After that, they are rinsed with water to remove any trace of clay or fines and then are stored.

For the smooth running of your quarry, the Haladjian Group offers you various solutions

For the proper functioning of your grinding and crushing installation, the Haladjian Minerals Solutions Service recommends preventive maintenance: avoid any breakdowns and stoppages in your production.

For an inspection of your installation contact us at + 33 4 90 39 39 55 or by email at clientshms@haladjian.fr

Haladjian Minerals Solutions also responds to all your requests for quotes and information for spare parts, wear parts and mechanical parts for your cone crushers, jaw crushers, impact crushers, screens, conveyors, ATM (metal apron feeders) … Contact us on 04 90 39 39 55 or by email at clientshms@haladjian.fr

Since 2019, the Haladjian Group has been an Epiroc® partner, offering you a wide range of drilling tools and Epiroc® spare parts for your drilling machine.

- Drilling tools for top hammers (TH): sleeves, rods, fittings, cutting edges, drill bits, guide tubes…

- Drilling tools for down-the-hole hammers (DTH): drill strings, down-the-hole hammers, bits, tubes & adaptors…

Would you like more information or a quote for spare parts on a drilling machine? Contact us at + 33 4 90 39 39 39.