Rebuild

Rebuild machine and rebuild program: the reconditioning of your crushing and grinding machines

A second life and savings for your quarry facilities

What is a rebuild program in the aggregates industry?

The rebuild program proposed by Haladjian Minerals Solutions aims to extend the life of crushing and grinding machines and mining components by remanufacturing them.

Our rebuild program allows your aggregates production equipment to regain its optimal performance.

This program is often requested by customers for mining crushing and grinding equipment as they reach the end of their life and need more maintenance. However, always with a view to facilitating your daily mining production activity, carrying out overhauls at different times during the lifespan of your equipment will improve your productivity, extend the operating time and reduce costs. A profitable investment straight away!

Our program consists of different degrees of rebuilding to best meet your needs:

Supply of rebuild kits made up of a bronze assembly, a lubrication pump and safety device

A complete rebuild: A change of all machine parts with our mining spare parts and wear parts in our workshops with the addition of all possible specific improvements.

With this program, our customers double the lifespan of their aggregates production equipment and avoid the cost of investing in a new crushing and grinding machine.

Stages of a rebuild program in the mining and mineral industry

As part of a rebuild, our experts in machine maintenance and repair follow several steps:

- Detailed inspection of your aggregates production equipment to define the intervention to be made on the crushing or grinding machine.

- Cleaning and disassembly of the equipment by our technicians, experts in the mining industry

- Carrying out a complete rebuild or assembly of the rebuild kit and replacement of the defective wearing parts of your aggregates production tool by our teams.

- Painting to finalize the refurbishment of your aggregates production equipment, it is repainted.

- Implementation of complete tests in our workshops of your mining equipment to verify the improvement of its performance.

- Delivery and commissioning of your equipment.

The Rebuild program, expertise to increase your performance

Each year, our experienced technicians in machine expertise carry out more than 30 rebuild machines.

These refurbishments are carried out on all types of equipment:

Metso® HP100, HP200, HP300, HP400, C110, C140…

Sandvik® CH440, CH660, CJ412, CJ612…

- Metso® HP100, HP200, HP300, HP400, C110, C140…

- Sandvik® CH440, CH660, CJ412, CJ612…

Discover our latest rebuilds:

Rebuild of a crusher

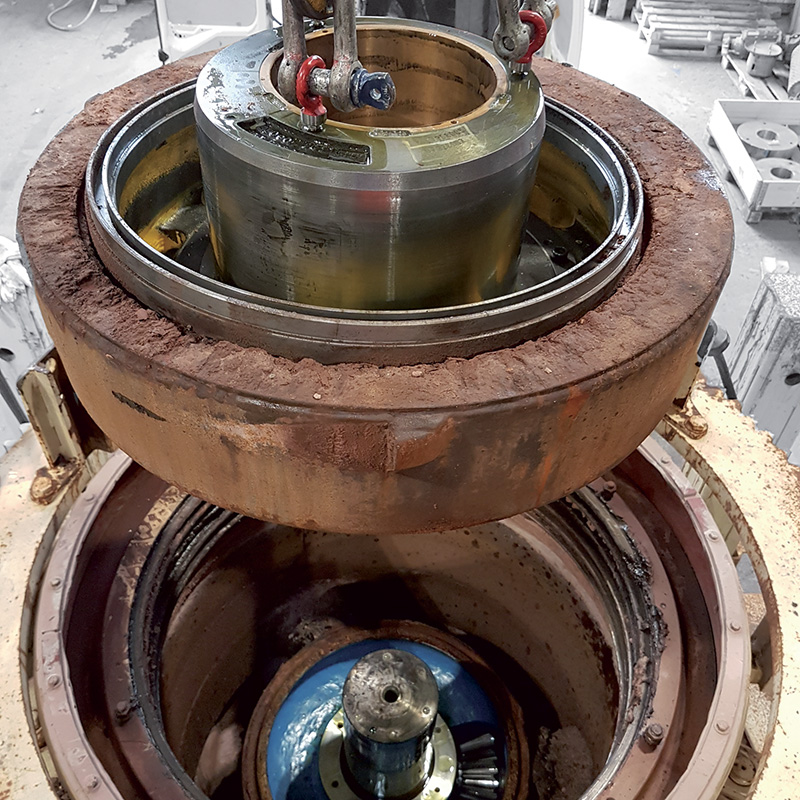

🛠Refurbishment by our teams of a secondary crusher for one of our customers with an alluvial quarry.

Actions taken:

✓ New frame assembly

✓ Adjustment and locking rings replaced

✓ New head assembly

✓ New security elements

=> Parts made in HMS>

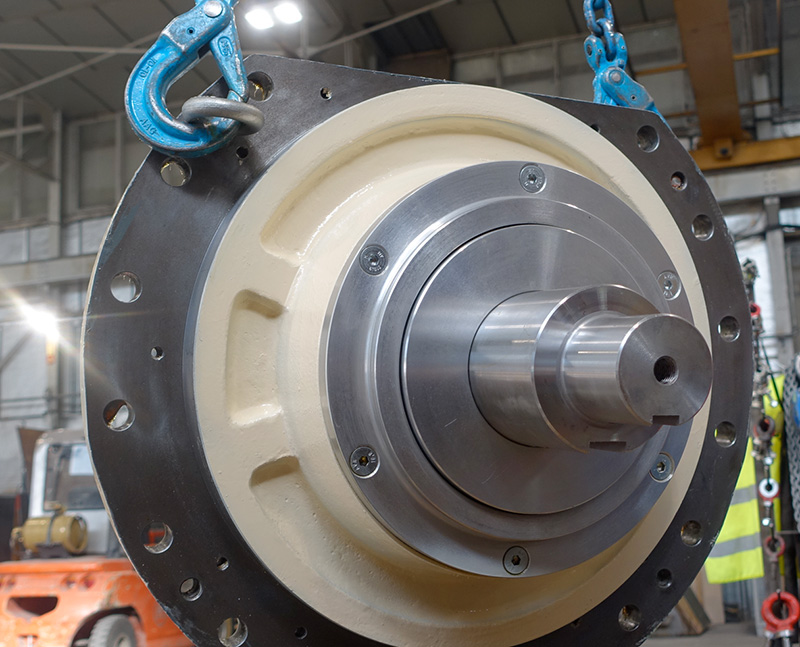

Rebuild of an HP300

🛠Refurbishment of an HP300 with the replacement of the frame made in Haladjian Minerals Solutions.

Rebuild of an Omnicone 937

🛠 Refurbishment of an Omnicone 937:

✓ Head ring, unbalance shielding, new lower and upper eccentric washers

✓ Counter-shaft wedging

✓ Tests

Our reconditioning programs:

Increase your productivity

Avoid shutdowns

Preserve your safety

NEWS

Lastet news

Rebuild machine programs

For your maintenances and shutdowns, plan your machine appraisals

If you plan a reduction or suspension of your activities, think about planning the maintenance of your crushing and grinding machines.

Rebuild of a BRH mounted on a mobile unit

Our experts in rebuild machine services for crushing and grinding machines have rebuilt a HRB mounted on a mobile group. This operation consisted in the

Rebuild of an HP200 grinder

Our team performed the rebuild of an HP200 grinder. To do so, our experts in rebuild machine services took specific actions with two different levels

Find out more...

Find out more about the Haladjian Group ang get to know better our missions, teams and especially our CSR policy.

Find out more about our machine maintenance and machine expertise solutions if ever you are looking to know what services we provide.

You want to increase the productivity of your aggregates production equipment? Find out more about our process study and optimization service or our facility design and our performance contracts solutions. Know more also about our mining process optimization service!

Check out our part’s calatlog where you will find the spare parts, the wear parts or the mechanical parts you need to repair, replace or rebuild your mining equipment.

Contact

Please contact us with any questions. Customer service: 201-244-7100 or hmaurer@haladjian.com