The operation of an impact crusher in a mine and aggregate production quarry

An impact crusher is necessary in a quarry in order to process different types of materials.

How does a percussion grinder work?

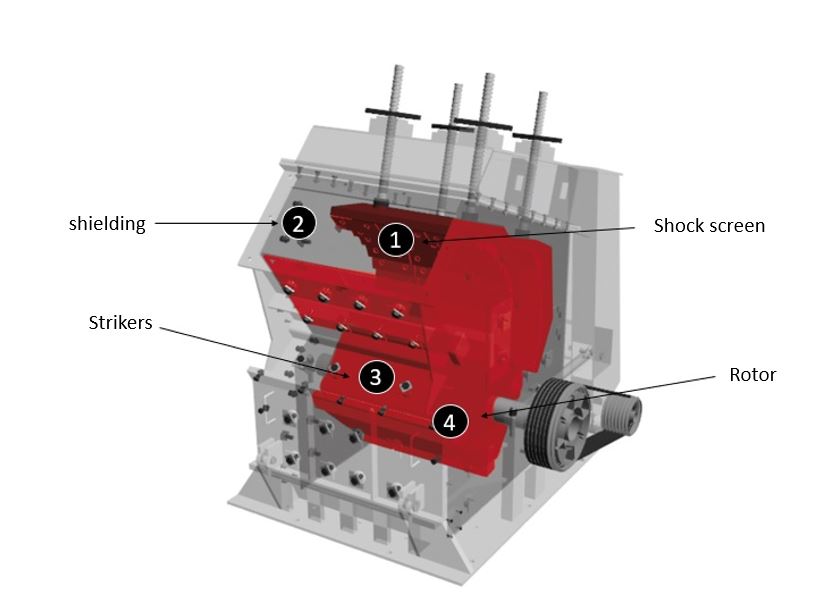

As the name suggests, the impact crusher works by percussion. With a high acceleration, the mineral product to be crushed is carried in a fast rotation of about 800 rpm by a rotor equipped with impactors that throws the rocks against the fixed walls, called the lining.

The crushing of the product takes place more exactly when the rock comes into direct contact with the impactors and the impact screens. At the end of the cycle at the outlet of the mill, the material is 6 to 8 times smaller than at the inlet.

The impact crusher is generally used in quarries for primary and secondary processing. It is suitable for crushing non-abrasive rocks such as limestone. It is also very effective in processing the recycling of inert waste materials such as concrete or asphalt.

What are the wearing parts of an impact crusher on a stationary or mobile plant?

Impactors

The impactors are metal bars that wear out very quickly and do 70% of the work. It is very important to check the height of the striker. If the height is below the specified value, the impactor must be turned over to start its second life.

The strikers can be made of different materials: manganese, chromium cast iron, martensitic with ceramic insert, chromium cast iron with ceramic insert.

Their resistance to abrasion is more or less random depending on the abrasion of the product.

Shock absorbers and shields

Shock absorbers with several shielding bodies made of a material with high wear resistance. They also wear out very quickly. There is a limit to how far the shielding should be used. If the limit is exceeded, the shielding must be replaced. The shielding is fixed on the horizontal side of the shock absorbers.

The wear of the shield has no impact on the quality of the production

Rotor

The rotor is equipped with a series of impactor that perform a rotation, which allows it by hitting and throwing the rock against the shock screens to achieve a crushing.

The rotor is in some way the centerpiece of the crusher.

A little more to know about the maintenance of your impact crusher

The chamber should be inspected once a week. Depending on the nature of the material to be processed, the service life of the impactors varies widely. The plates have twice the life of the impactors and the liners have twice the life of the impact screens. Read this article to know more about the the role of an impact crusher in quarries.

Haladjian Minerals Solutions is your supplier of spare parts for your impact crushers but not only, also for cone crushers and jaw crushers.

You need to carry out the maintenance of your crusher?

Our technicians will come to you to change your wear parts or mechanical parts.

Your Haladjian Minerals Solutions Customer Service is available for any question / quotation on +33 (0)4 90 39 39 55 or by email hms@haladjian.fr.

Need more information about mining equipment and the services available for the mining industry. Read our collection of articles that deal with crushing and grinding machines and aggregates production services.